Monitor STP Performance Remotely, Effortlessly & in Real-Time

Why Smart IoT for Sewage Treatment Plants?

IoT-driven STP monitoring ensures treatment efficiency, regulatory compliance, and reduced operational and energy costs.

- Real-time utilities monitoring

- Automated Alerts

- Remote Control & Diagnostics

- Compliance Reporting

- Centralized multi-site control

Smart Building Strategy

Small STPs

- ○ Compact IoT kits with plug-and-play sensors.

- ○ Mobile app-based dashboards.

- ○ Energy & water usage optimization.

Mid-Sized STPs

- ○ Integrated flow + water quality sensors.

- ○ Predictive maintenance with AI insights.

- ○ Edge Gateway with Redundancy.

Large STPs

- ○ Multi-site SCADA/IoT integration.

- ○ GPS-enabled tanker tracking for sludge/sewage.

- ○ Automated compliance data logging.

Smart Solutions by Application

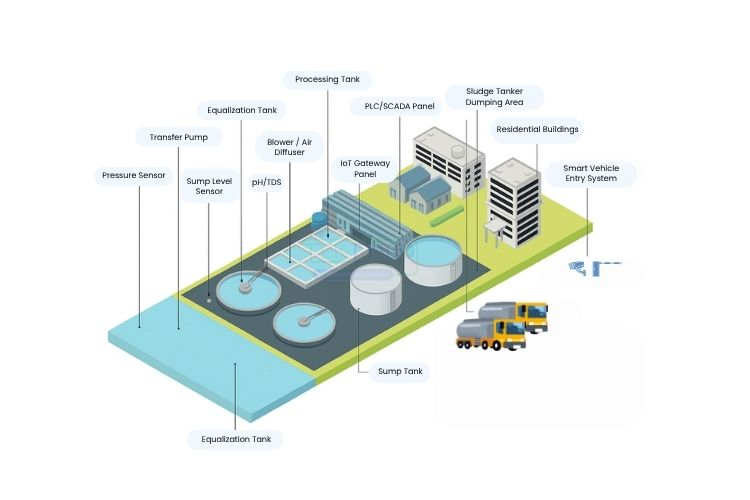

Inflow Monitoring

- • Ultrasonic and electromagnetic flow sensors to measure inflow volume and velocity with high accuracy.

- • IoT gateways for continuous data logging and real-time cloud analytics.

- • Pressure and level sensors to detect inlet blockages, surges, or overflow risks early.

- • Automated alerts and reports for abnormal inflow conditions or supply interruptions.

Benefits: Accurately track every drop entering the STP and optimize operations from the very first treatment stage.

Treatment Process Monitoring

- • Dissolved Oxygen (DO) sensors to monitor aeration efficiency and microbial activity.

- • pH, ORP, turbidity, temperature, and conductivity sensors for real-time treatment quality tracking.

- • Smart controller integration to automatically adjust blower speeds and chemical dosing.

- • Cloud-based data logging and analytics to identify long-term performance trends.

Benefits: Maintain stable biological and chemical treatment processes while ensuring continuous PCB compliance.

Tank Level & Pump Health Monitoring

- • Ultrasonic or radar level sensors for real-time monitoring of aeration, storage, and equalization tanks.

- • Vibration and temperature sensors for early detection of pump and motor bearing faults.

- • Smart relay-based automation for pump start/stop based on levels and energy usage.

- • Predictive maintenance alerts with solar or UPS backup for uninterrupted operation.

Benefits: Prevent overflows, dry runs, and equipment failures while extending pump and motor life.

Energy Consumption Monitoring

- • Smart energy meters for pumps, blowers, aerators, and treatment units.

- • Real-time load analysis to detect current spikes, inefficiencies, and phase imbalance.

- • Automated scheduling for off-peak operation and energy cost optimization.

- • Power factor, voltage logging, and ESG-ready energy reporting.

Benefits: Reduce operational energy costs while improving efficiency and meeting sustainability goals.

Sludge & Tanker Tracking

- • GPS-based live tracking of sludge tankers from pickup to disposal points.

- • RFID or QR tagging to authenticate tankers and authorized disposal locations.

- • Geo-fencing alerts for route deviation, delays, or unauthorized dumping.

- • Centralized dashboard integrating sludge movement with STP inflow and outflow data.

Benefits: Ensure full transparency and regulatory compliance in sludge transportation and disposal.

Discharge Quality Monitoring

- • Online BOD, COD, and TSS analyzers for continuous effluent quality monitoring.

- • pH, ORP, and ammonia sensors to verify treated water meets discharge and reuse standards.

- • Automatic IoT data transmission for PCB reporting and audit readiness.

- • Real-time alerts and cloud-based compliance reports.

Benefits: Achieve zero non-compliance with live effluent quality analytics at the discharge point.

Safety & Security

- • NVR-based CCTV integration for plant-wide surveillance.

- • Magnetic door sensors and smart locks for restricted access control.

- • Fire Alarm Control Panel (FACP) status monitoring for emergency response.

Benefits: Ensure staff safety and secure plant operations with multi-layered protection.

End-to-End Smart STP Monitoring From Inflow to Discharge & Sludge Transport

Connect silos and visualize your entire facility's pulse in real-time.

One Dashboard. Complete Control.

Centralized control of all building assets and alarms.

- Real-time alerts for anomalies

- Customizable reports for facility teams.

- Predictive analytics to reduce downtime.

- Mobile/Desktop access.

- Role-based access control

Why Choose TEK DEPO?

Consultative Deployment

We design solutions around your assets' unique footprint.

Future-Ready Hardware

Scalable sensors, relays, and gateways.

Actionable Analytics

Analytics that help you make decisions, not just collect data.

Dedicated Support

Remote + onsite assistance for zero disruption.

Transform Your STP into a Smart, Self-Monitoring System

Discover how smart monitoring can lower downtime, boost efficiency, and bring your facility under complete control.

Frequently Asked Questions

Find answers to common questions about our smart building solutions

Can the system integrate with existing STP infrastructure?

Yes. TEK DEPO’s IoT gateways and sensors are designed for seamless retrofitting into existing STPs without disrupting ongoing operations.

What kind of sensors are used in Smart STP monitoring?

The solution uses IoT-enabled DO, pH, TDS, turbidity, ORP, level, flow, temperature sensors, along with GPS modules for sludge tanker tracking.

How does this help with regulatory compliance?

All treatment and discharge parameters are logged automatically and stored as audit-ready cloud reports, significantly reducing compliance risks.

Can the solution be customized for specific requirements?

Yes. Every STP has unique equipment and layouts. TEK DEPO follows a consultative approach to assess your plant and recommend tailored sensors, controllers, and dashboards.

What support does TEK DEPO provide after installation?

TEK DEPO provides training, customization, remote monitoring assistance, and dedicated technical support to ensure minimal downtime and smooth operations.

Still have questions?

Contact Our Team